Solar panel recycling equipment (reset recycling)

Efforts towards the Sustainable Development Goals (UN-SDGs)

SDG Targeted

Target 7.2

By 2030, reduce waste by more than 80% through the recycling of solar panels and create

sustainable,

eco-friendly energy by producing clean electricity using renewable energy solar power.

End-of-Life Solar Panel Recycling Center

Solar waste issue starting soon

By reducing the amount of discarded solar waste, we are creating environmental, social,

and economic impacts.

By reducing the waste that power generation companies throw away through Reset's panel

separation equipment, we are reducing processing costs and recycling clean materials to

generate additional profits, providing a win-win environment for companies and

customers.

Solar waste panel automated separation technology

Solar panels are bulky and heavy, and recyclable materials such as aluminum and tempered

glass must be separated, reduced, and discarded.

(Composition: 76% tempered glass, 8% aluminum, 10% polymer, 5% silicon, 1% copper, 0.1%

silver)

Reset Solution

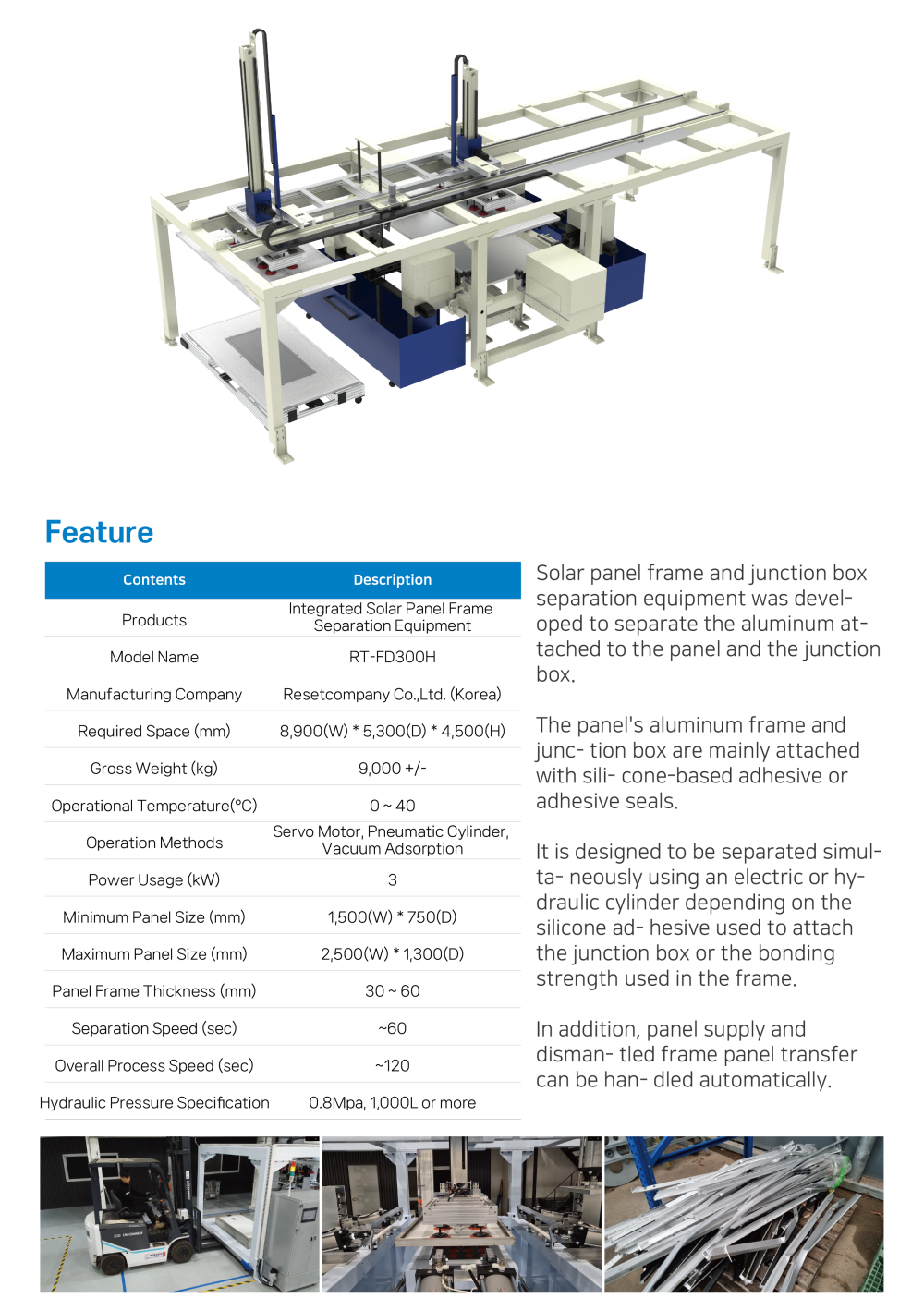

Integrated solar panel frame separation equipment

Solar panel tempered glass separation equipment